Know part integrity with certainty

A superior NDT inspection

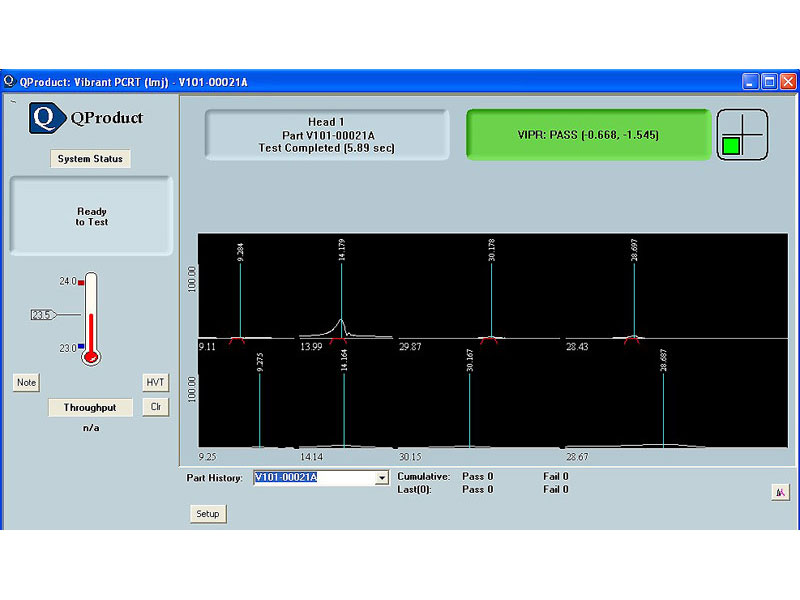

Vibrant’s patented PCRT technology includes proprietary software and user-friendly hardware. Programmable by Vibrant to inspect your specific parts to your specifications, PCRT is scalable and capable of varying levels of automation for rapid, clear inspections of every part.

How PCRT works

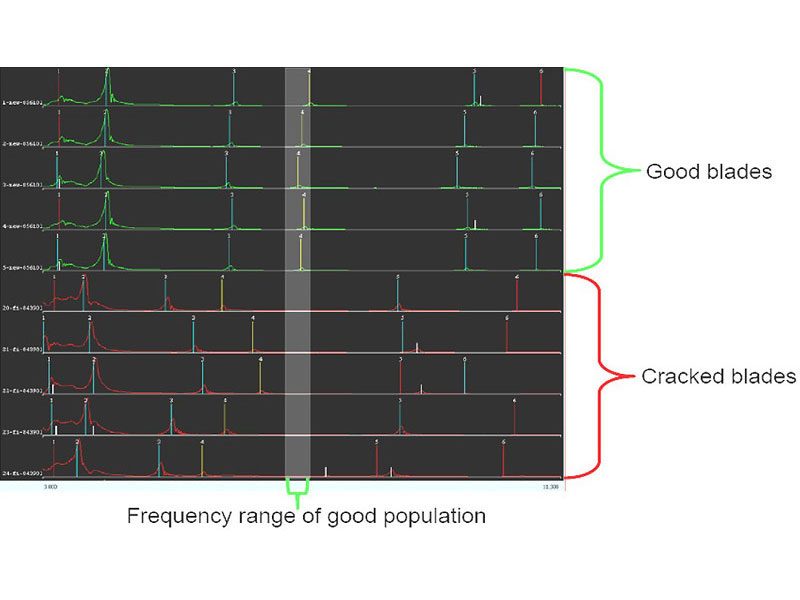

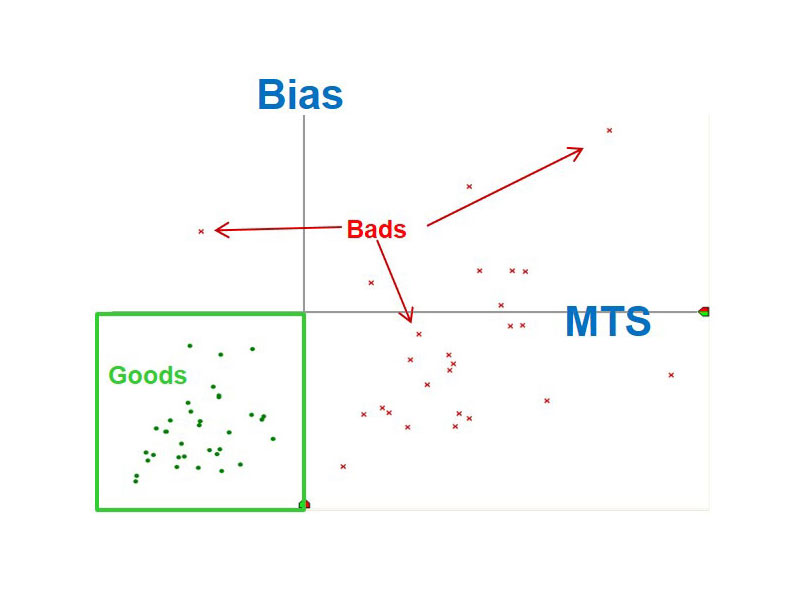

PCRT measures the resonance frequencies of whole parts, combining the collection of broadband resonance data in the ultrasonic frequency range with advanced pattern recognition to produce an accurate, fast and automated nondestructive inspection. Parts with flaws or changes in material and geometric properties affecting structural performance are immediately detected and flagged.

Where simple resonance analysis is insufficient for defect detection due to interlaced acceptable and unacceptable patterns, PCRT features a subset of spectra for immediate pattern recognition. The pattern recognition and scoring tools return an automated PASS/FAIL result that requires no operator interpretation, allowing for rapid, confident testing.

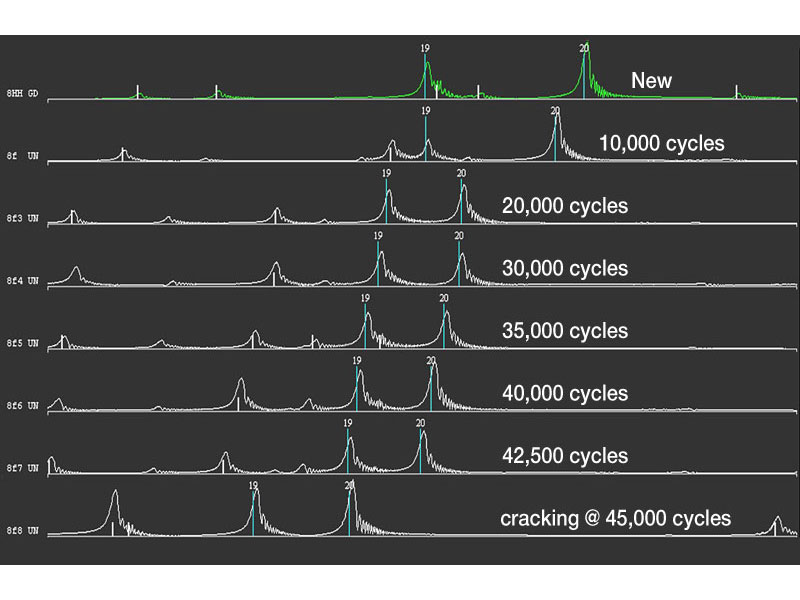

Frequency, scoring data and part/lot serialization are stored digitally for traceability and process monitoring and control. This data can also be utilized to monitor parts throughout service life to detect the accumulation of fatigue, opening opportunities to confidently extend service life without added risk.

PCRT tests for (but is not limited to) the following:

- Porosity

- Lack of Fusion

- Inclusions

- Oxides/Corrosion

- Inter Granular Attack

- Voids

- Tensile Strength

- Residual Stress

Take a more detailed view through this presentation on the basic methodologies of PCRT:

Vibrant’s Testing Technology

Vibrant PCRT uses Vibrational Pattern Recognition (VIPR) and RUSpec software packages. VIPR is a set of tools that identifies diagnostic resonance frequency patterns and statistically scores them to yield test results. For PASS/FAIL NDT applications, VIPR scores can be used for outlier screening and/or targeted defect detection, typically taking less than 15 seconds per part. Pass/Fail decision making is fully automated, requiring no operator interpretation. Scores can also be used for monitoring and control of established and new manufacturing or repair processes.

Parts requiring periodic maintenance and inspection can be monitored over their lifetime by tracking stored resonance frequency and VIPR scoring data from each shop visit.

RUSpec software determines engineering material properties for material samples using measured resonance frequencies. RUSpec performs an iterative fit of the modeled resonance frequencies to the measured ones, and outputs the corresponding engineering material properties for the measured frequency data. The output material properties include Young’s Modulus, Bulk Modulus, Shear Modulus and Poisson’s Ratio.

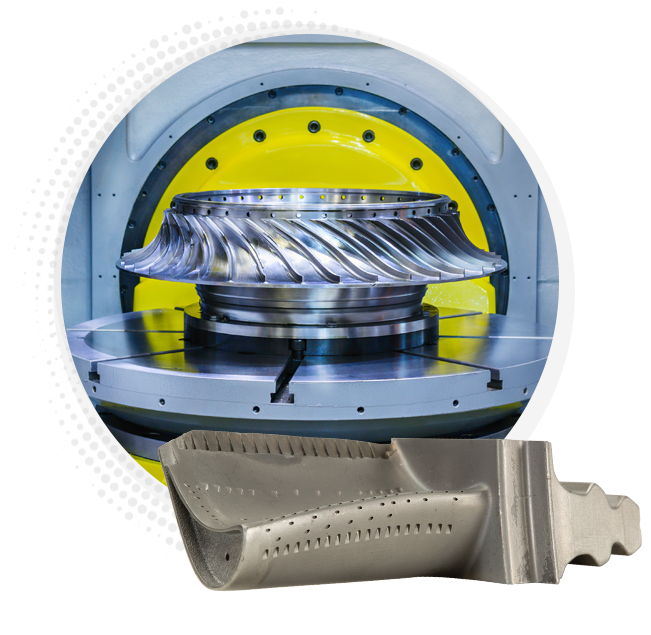

Configurable for a very broad variation of part geometries and materials, PCRT systems are scalable for customer part sizes, from half-inch ceramic rolling elements to wide-body airliner landing gear struts. PCRT scales with your volume as it evolves, from a handful of parts to large lots, with varying levels of automation from hand-loading to fully automated part handling.

PCRT System hardware includes:

- “Nest”: Fixtures part with three PZT piezoelectric transducers (1 drive, 2 receive channels)

- Transceiver: A high-end signal generator/processor

- Control Computer: Standard laptop or desktop PC equipped with Vibrant’s proprietary PCRT software

Vibrant Automated PCRT System for Turbine Blade Castings

Vibrant Automated PCRT System for Aircraft Wheels

Cobotic PCRT Bolt Inspection System by Vibrant and Build with Robots

Your PCRT

Call us today to learn more about our system and how it can be configured to meet your NDT needs, putting you on the path to reduced part failures.