Changing the way you think about inspection and maintenance

Innovative testing solutions

Vibrant’s PCRT technology challenges today’s inspection and maintenance mindset, opening the door for new, progressive and economical opportunities to increase reliability and reduce part failure.

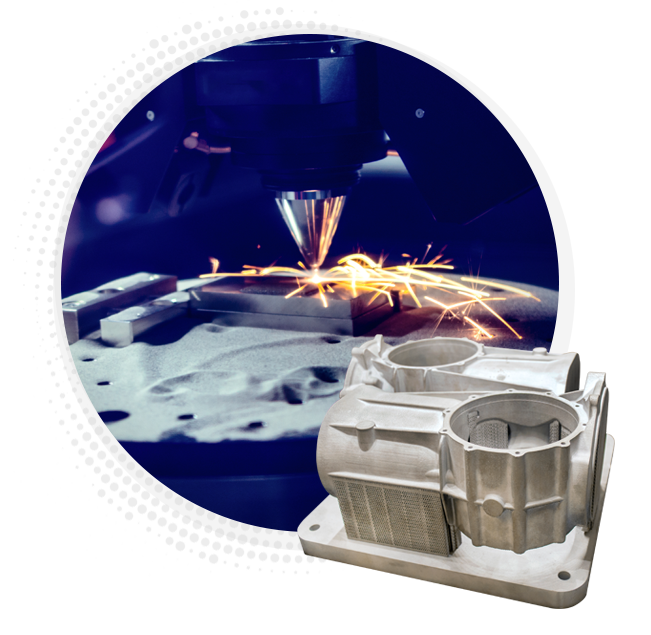

Additive Manufacturing

As additive manufacturing gains acceptance in the industry, there is considerable demand for reliable, accurate testing. Unlike traditional NDT methods that struggle with the geometric complexities of additive manufacturing parts, Vibrant’s PCRT technology delivers whole part inspections, returning clear data illustrating part integrity.

With manufacturing advancements comes the need for advanced testing to ensure parts are made correctly, safely and will not fail. While traditional NDT has not kept up with changing processes like Additive Manufacturing, Vibrant’s PCRT is already ensuring part reliability.

Advanced Modeling

Advanced Modeling allows Vibrant to go much deeper than a Pass/Fail reading for a part. With this technology we create scenarios in design, material properties, stresses, and many other variables to better understand resonance frequency changes and decode outlier signals. Through creation of 3D models, we characterize material and part defects, gaining a deep understanding of exactly what caused the fail reading. The data is then available to support efforts to reduce these defects or failures, whether on the manufacturing or operating side, and better predict future failures.

Advanced Modeling also supports initial test set up for customers. Customers are typically asked to supply good and undesirable parts to develop baselines for initial parts tests. Advanced Modeling allows us to replace this requirement when part design data is available to replicate the part accurately in a 3D model.

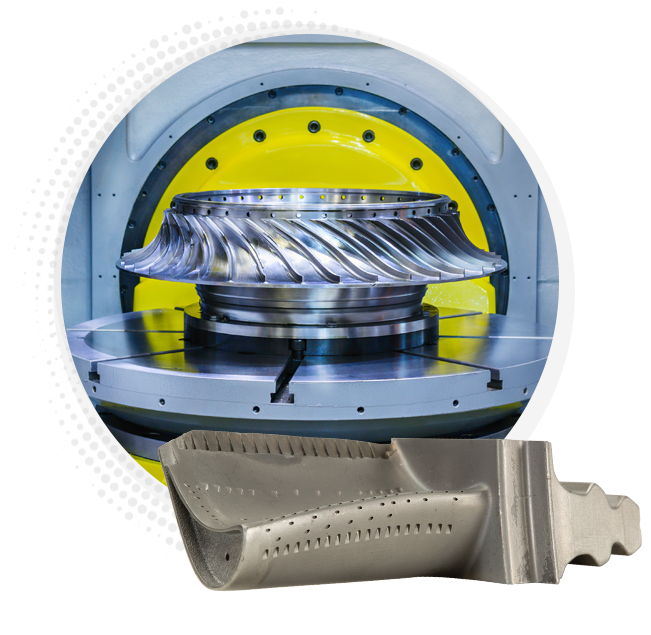

In-Situ Monitoring and Testing

Currently in the testing phases, in-situ monitoring and testing allows specific parts to be tested while still assembled. Imagine the cost and time savings possible with the ability to test and monitor turbine fan blades while still inside the assembled engine, for example.

We’re seeking a testing partner interested in working with us to further explore this progressive opportunity for PCRT.

Big Data

When your inspection focuses only on the area that failed in the last part, you could be missing other indications of pending risk. Vibrant’s technology gathers far more than prescribed parameters, and collects this information over time. This big data gives you a whole new view of part performance and integrity, allowing you to extend life, retire a part before failure, or even change inspection routines with the confidence you have the data to back the decision and increase reliability.

Discover how PCRT Technology can help you

Contact us to learn more about our PCRT technology and its advancements that can change how you perform NDT.