The faster, cleaner, more reliable NDT inspection method

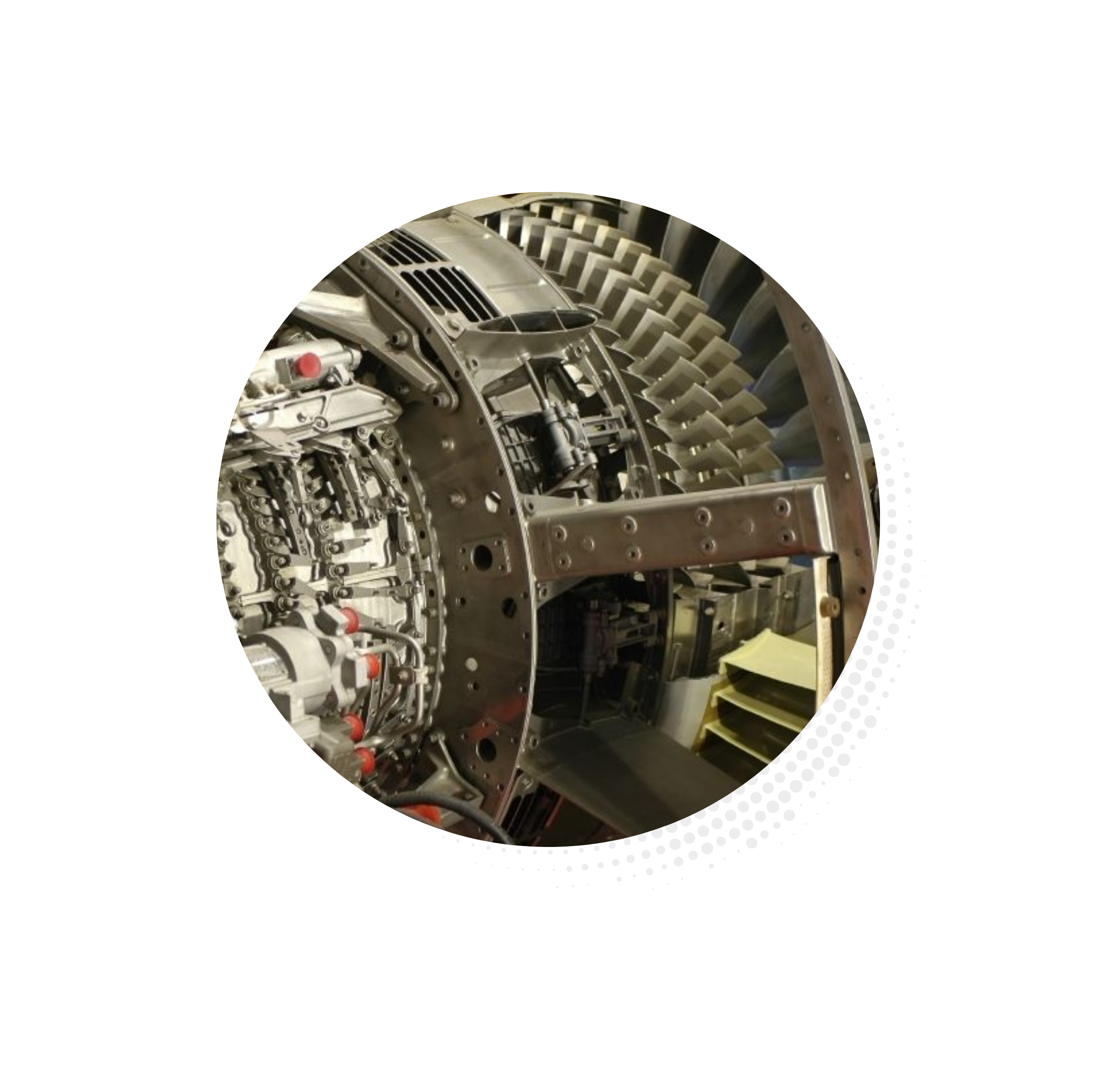

PCRT FOR TURBINE BLADES

Winner of the FAA-ATA Better Way Award and the SAE NDT Better Way Award

Process Compensation Resonance Testing (PCRT) is a whole-part resonance inspection method that effectively detects damage in turbine blades with higher quality results compared to liquid penetrant inspection. PCRT also features minimized part handling and does not require the blade to be cleaned or the coating to be removed before testing, saving valuable time and reducing waste.

Efficient Turbine Blade Inspections

PCRT provides operators and MROs with a faster, less intrusive, and cleaner NDT method for turbine blades. Each blade is quickly tested in as little as five seconds without the need to clean it or remove its coating, significantly shortening testing times. PCRT is also fully automated, requiring no training or specialized skill from operators.

Vibrant’s PCRT performs outlier screening and targeted defect detection on production and in-service turbine blades. Resonance frequency data is recorded and analyzed against algorithms and statistical scoring, returning a clear pass/fail result, eliminating operator misinterpretation.

Benefits

- Improved efficiency: cleaning and coating removal not required for PCRT inspection

- High accuracy with a reduction in false reject rates

- Test higher volumes faster than traditional NDT

- Automated testing eliminates subjective operator interpretation

- More sustainable: eliminates excess blasting media, penetrants, and coating waste

- Defects discovered that penetrants and eddy currents miss

- Up to 90% reduction in inspection time

How Turbine Blade PCRT Works

Each turbine blade is placed on the PCRT test nest either manually or robotically. The part’s temperature is taken, the test is run, and a pass or fail indication is provided. Each test takes between 5 seconds and 3 minutes. Test results and resonance data are stored by serial number for future reference and use in PTI sorting for future tests. The blade does not need to be cleaned before testing and coating does not need to be removed.

The PCRT system is a ‘direct reading instrument.’ It does not require the operator to be certified NDT personnel.

Operators or MROs can arrange to have PCRT equipment installed in their shops or to ship parts to Vibrant for testing. Vibrant bills on a per-part-tested model, where the fee reduces per part as volumes increase.

A Better NDT Solution

Are you experiencing recurring issues not discovered by your current NDT? Are you seeking a different kind of inspection that is faster, cleaner, and free of operator interpretation? PCRT is your solution. Contact us today to learn more.