It was an exciting summer for the Vibrant team as a family of Digital Twin patents were issued. Congratulations to Vibrant inventors Thomas Köhler, Julieanne Heffernan and Leanne Jauriqui. Many thanks to our legal counsel, Jon Deppe of Holzer Patel Drennan.

Vibrant was awarded a group of patents titled ‘Digital Twin Model Inversion for Testing’, including patents 11,371,965 and 11,371,966, cover the use of PCRT data in Digital Twin programs – specifically using PCRT data to validate model assumptions, combining simulated and physical measurements to inspect and sort parts, and to determine optimal maintenance and inspection cycles.

Much of an engineer’s work today is in a simulated realm. We want (and need) to harness the power of the computer to help us predict what will happen in the physical world. As we all know, the value of these simulations is only as good as the model inputs.

- How do we know exactly what a component’s operating environment will look like?

- How do we know the stresses or temperatures?

- How do we know the material properties and material state descriptors (like residual stress) of the component itself?

- How far off can we be before our simulated performance is no longer applicable?

These are certainly the questions that the next generation of engineers will try to answer with as much digital support as possible.

PCRT and Digital Twin

PCRT can support Digital Twin programs in a variety of ways.

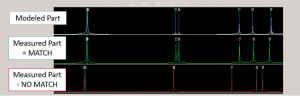

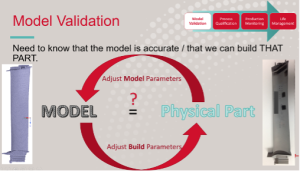

Some groups are using a Digital Twin for virtual/simulated testing of physical components. A model is built that is supposed to represent the physical part that is produced. The model is then subjected to a variety of simulated conditions, to assure that the physical part will perform adequately. PCRT can be used to verify that the model accurately represents the material properties of the physical part. Resonance frequencies are determined by a component’s material properties and dimensions. Finite element tools can readily predict resonance frequencies for simulated components. We can compare MEASUREMENTS of the resonance frequencies to MODELS of the resonance frequencies and assess the accuracy of our model. This is the basic concept of Resonant Ultrasound Spectroscopy – one of the first quantitative applications of resonance inspection. We can also create a multi-parameter (Monte Carlo) population of models that can be used with regression-type optimizations to invert the modeled material properties that best match the resonance response of our physical components.

Sometimes organizations work first on the virtual part design and do a lot of simulated testing assuming that the part will be built with the modeled material properties. When parts are actually physically produced, we need to know that they match all the assumptions of the digital design. PCRT model inversion and population comparisons can be used to validate that the physical parts match the digital design intent.

Digital Twin and Part Defects

Digital Twin models may also be used to represent the state of parts in a damaged condition. Real defects are hard to come by – hard to make and harder to find. If we work to simulate defective conditions, we need to validate that these accurately reflect what is seen in physical parts. Again, a modal analysis/resonance comparison can help to determine how accurate the model represents the physical part.

Digital Twin and Aerospace Parts

In aerospace parts, we might help maintain digital twins of expensive components. Rather than treat all components as we would the worst/weakest of them, we can quantify, sort and group parts into sub-groups that might have different maintenance requirements, or different life limits. Sub-groups might be determined by a new part’s material properties or dimensions, or they might be related to operating conditions or environmental factors. Organizations looking to take advantage of differences in their part population to optimize MRO intervals or life limits need ways to validate model assumptions. PCRT inspections can also provide extra quantitative evidence that a part belongs in a particular sub-group.

Digital Twin and PCRT Can Improve your Efficiency

Vibrant and PCRT are well positioned to help you rely more on simulated results, by giving you the ability to validate these models with precise physical resonance measurements. Contact Vibrant today to talk about how PCRT can help your Digital Twin programs.